Three-Stage Paint System: Enhancing Vehicle Finish Effortlessly

The three-stage paint system is a game-changer in automotive body painting, offering enhanced durabi…….

In the dynamic world of coatings and finishes, the three-stage paint system has emerged as a revolutionary approach, offering enhanced performance, durability, and environmental friendliness. This innovative technology is transforming industries, from automotive and aerospace to architecture and decor, by providing superior aesthetic value and longevity. In this article, we embark on a thorough exploration of the three-stage paint system, uncovering its intricate design, global impact, economic implications, technological advancements, regulatory landscape, and future potential. By delving into these aspects, readers will gain a comprehensive understanding of why this paint system is making waves across various sectors.

A three-stage paint system, also known as a multi-layer coating system or advanced paint technology, is an innovative approach to surface protection and decoration that involves three distinct layers:

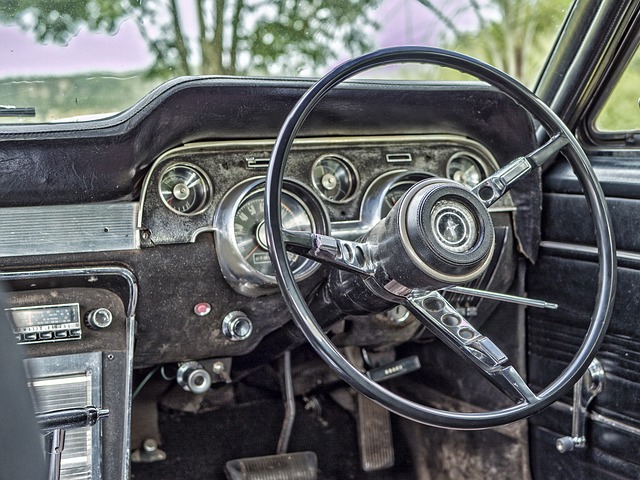

The concept of multi-stage paint systems can be traced back to the early 20th century when industries sought better solutions for protecting metal surfaces. Traditional single-coat paints often lacked adhesion and durability, leading to premature failure, especially in harsh environments. Over time, researchers and manufacturers developed more sophisticated systems, incorporating specialized primers and top coats, which laid the groundwork for today’s three-stage paint technology.

This evolution was driven by several factors:

The three-stage paint system offers several key advantages:

These benefits have made the three-stage paint system applicable across diverse sectors:

The three-stage paint system has left its mark on a global scale, influencing painting practices and products in numerous countries. Its adoption varies across regions due to factors such as local regulations, economic conditions, and cultural preferences. Here’s an overview of its international impact:

Several trends are set to influence the three-stage paint system’s evolution:

The three-stage paint system plays a pivotal role in various economic sectors, with significant market dynamics at play:

The global paints and coatings market, including three-stage systems, is substantial and growing. According to a 2022 report by Grand View Research, the market size was valued at USD 186.4 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 5.7% from 2022 to 2030. This growth is attributed to rising construction activities, increasing automotive production, and growing demand for decorative finishes.

The market is segmented based on various factors:

The three-stage paint system contributes to economic growth and development in several ways:

Technological breakthroughs have been instrumental in refining the three-stage paint system, pushing its performance boundaries and opening new possibilities. Here are some significant advancements:

Incorporating nanoparticles into paint formulations has led to remarkable improvements:

The integration of smart materials and sensors into paint systems offers potential for:

The marriage of digital technology and paint systems has revolutionized customization:

The three-stage paint system is subject to various policies and regulations that govern its production, use, and environmental impact, ensuring safety, quality, and sustainability.

Given the growing focus on environmental protection, many countries have implemented strict guidelines for paints and coatings:

To ensure worker safety and product quality, several standards and certifications are in place:

International trade in paints is subject to various agreements and standards:

Despite its numerous advantages, the three-stage paint system faces challenges and criticisms that require thoughtful solutions.

One primary concern is the potential higher cost associated with advanced multi-stage paints compared to traditional single-coat systems. This can limit accessibility, especially in price-sensitive markets or for smaller-scale projects. To address this:

Proper application is crucial for achieving optimal results with three-stage paints. Inadequate preparation, incorrect sequence of coats, or substandard equipment can lead to poor performance and premature failure:

While significant strides have been made in reducing VOCs and improving sustainability, some environmental critics argue that the presence of certain chemical components in advanced paints still raises concerns:

BMW, the German automotive giant, implemented a cutting-edge three-stage paint system in their manufacturing process, achieving remarkable results. The system includes an advanced primer that provides excellent corrosion protection and a unique clear coat with UV-absorbing properties, ensuring long-lasting color and gloss.

Key Takeaways:

A major construction project in New York City incorporated three-stage paints as part of its sustainable design, focusing on durability and environmental friendliness. The building’s exterior walls were coated with a low-VOC, water-based three-stage system, offering exceptional weather resistance and long-term color retention.

Case Analysis:

The three-stage paint system is poised to evolve and expand its reach in various sectors, driven by technological advancements and shifting market demands.

Several trends will shape the future:

Innovation in the following areas will have a significant impact:

The three-stage paint system has emerged as a powerful solution, offering unparalleled durability, aesthetics, and customization options across various industries. As technology advances and environmental consciousness grows, this innovative product category will continue to evolve, addressing challenges while unlocking exciting new possibilities. By embracing technological advancements, sustainable practices, and tailored solutions, the three-stage paint system is poised to play a pivotal role in shaping a more vibrant, durable, and environmentally responsible future.

The three-stage paint system is a game-changer in automotive body painting, offering enhanced durabi…….

The three-stage paint system is a meticulous process for achieving high-quality, durable finishes in…….

The three-stage paint system is a meticulous, 3-layer process (primer, color coat, clear coat) desig…….

The three-stage paint system is a revolutionary automotive exterior finishing method, offering super…….

The three-stage paint system is a versatile and essential approach for high-quality custom paint job…….

The three-stage paint system is a revolutionary approach in automotive restoration, offering precisi…….

A flawless three-stage paint system demands meticulous surface preparation: cleaning, decontaminatin…….